This is my latest COVID-19 project and its turned into a real saga. Once upon a time a few years ago I had a very pretty Phoenix MXS in red, white and blue …

Some Background …

… but I had a lot of trouble getting the Evo .60 to run properly. It was an early version which used muffler pressure to get fuel to the carby and I never got it to idle. Another feature was a very large (and long) muffler. The upshot was I eventually stalled the engine and ended in the farmers field nose first into the upslope with the U/C taking all the landing strain. The MXS went to the naughty corner for a few years and the Evo .60 was sold.

It seemed like a good idea at the time …

Now comes COVID-19 and I think I’ll fix the MXS so ordered carbon fibre landing gear (not yet arrived) and I start looking at what I can do to the cowling which has large holes everywhere. Another feature of the cowling is that it has curves, double curves and triple curves and air intakes everywhere with almost no flat surfaces.

In essence my idea was:

- fill the holes with something,

- fibreglass in behind the holes to strengthen everything,

- use filler over the outside to smooth it all out, and

- then spray the cowling to restore its former beauty

simples.

The Method and the Madness

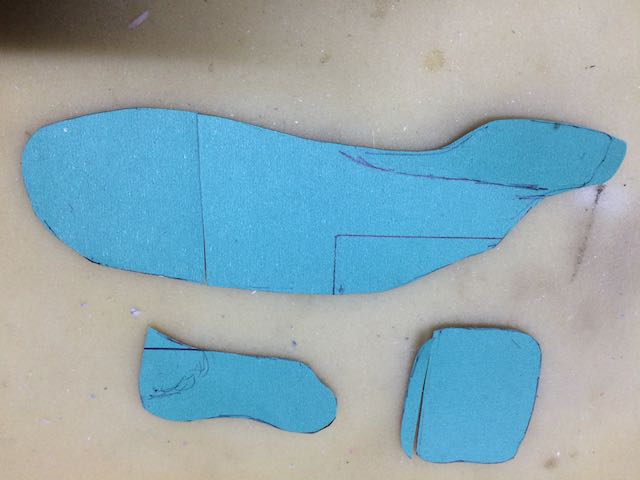

Before starting I made some (rough) templates of the openings I planned to fill from soft cardboard. I wasn’t sure if I would need them but it seemed like a good idea.

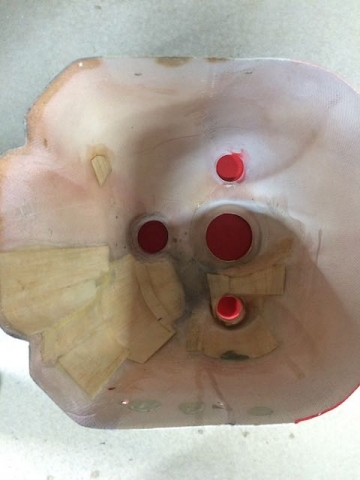

The substrate I used to fill the holes was 1mm balsa sheet because it was fairly flexible and, if necessary I could dampen it to go around tight curves. After that the initial stage was a bit like a jigsaw puzzle but you had to make your own pieces. After all the holes were filled I fibreglassed the inside and then use more 1mm balsa to finish filling the gap between the inner balsa layer and the outer layer of the cowling (did I mention that that cowling is just under 1mm thick). Then lots of sanding.

Next I skinned all the balsa with a 2 part fibreglass body filler then more sanding. One air intake had to be rebuilt from scratch so I used a ready mixed epoxy putty to mould the rim of the intake. More sanding with some filing just for a change.

Then I had a good idea, I would go over all the body filler and balsa with a fibreglass resin flow coat (white) … and then more sanding but with wet or dry in several grades.

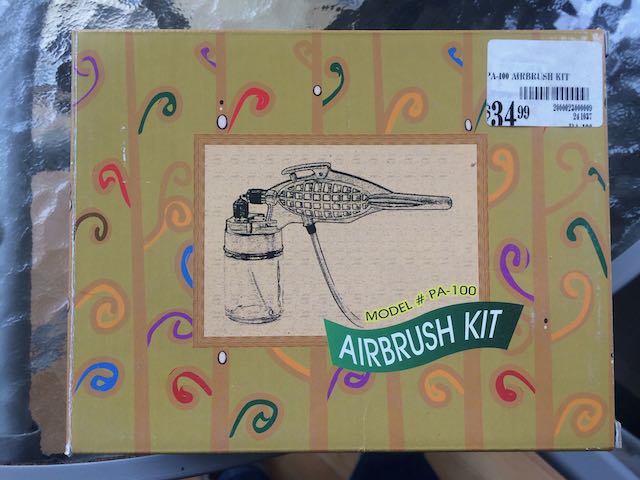

Eventually I got fed up and decided I would start painting with my high quality $35 airbrush. The only paint I could get was Tamiya blue and white (everyone must be using red as there was none in Tamiya, Humbrol or about 3 other paint brands), so blue and white is what I did first.

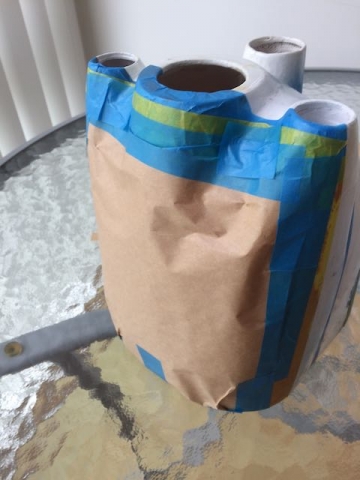

The blue went on very easily and covered a multitude of sins but I didn’t mask up enough so there was lots of overspray. I let it all dry overnight and then masked up to apply the white. Having learnt a bit from yesterday’s mistakes I masked everything with particular attention to the edges and then covered the red and blue with brown paper. I used lots of white trying to cover the overspray (I was too lazy to rub it down first).

When I took off the masking tape I also pulled off some of yesterday’s blue paint so more work for next time.

Each time I was applying fibreglass, flow coat or paint the weather was cold so Mary’s hairdryer and our little backup fan heater got quite a workout.

Wow, that’s a real labour of love. The finished cowl looks great Neil. Thanks for the in-depth description. Is the plane ready to fly again now?

It’s not quite ready to fly. I’m still waiting for the replacement landing gear to arrive and I don’t have an engine for it. I’ve been trying to decide which engine to get but it looks like the best fit will be a Saito FG11 which is just beyond my budget at the moment!

You’re right that the amount of work involved is way over the top. The plane was sitting in the garage for several years and if not for COVID-19 would probably still be there! For the amount I’ve spent fixing the cowling I could have bought a new plane.

Strewth Neil, what a job and it looks like it turned out pretty well. I guess the next step will be to give it a fly, how are your nerves?

Regards

Trevor

An enormous amount of work Neil. This plane looked great when new and the cowl looks great now. I hope the MXS returns to its former glory. Great job.

Still a way to go to get everything finished. As long as the coronavirus lockdown continues there’s hope I’ll get it all done.

Don’t worry….there’s probably a second wave of COVID just around the corner….😉

Hello everybody

I have been looking at the comments on Neil’s labour of love it dose look good ,a lot of work 👷♂️